AI-LINK Showcases Its Latest Innovations at SPS Nuremberg 2023

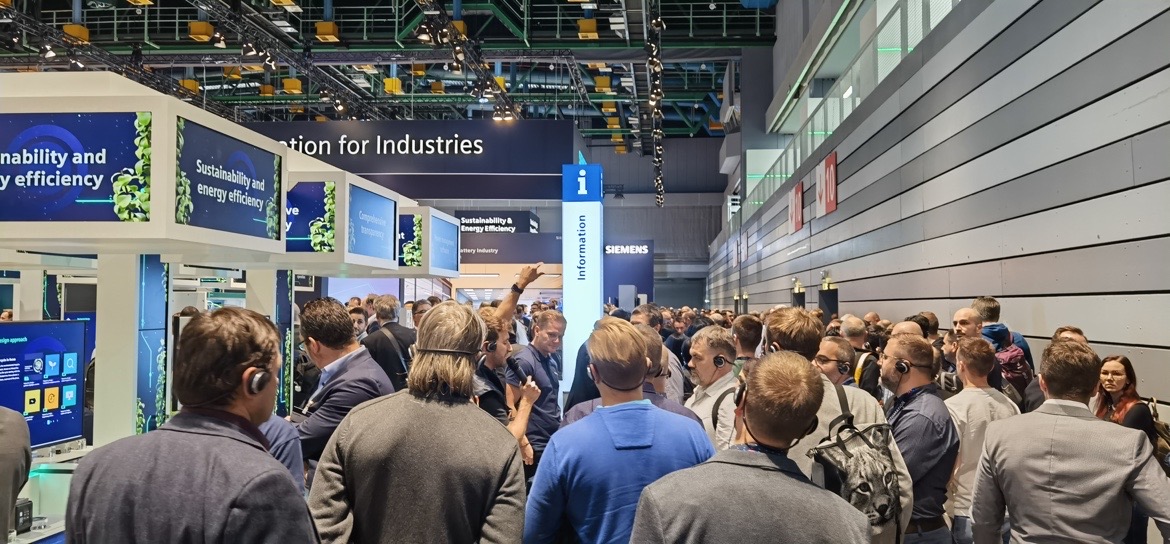

The Smart Production Solutions trade fair (SPS Nuremberg 2023) concluded on November 16, 2023 local time. As a leading event for industrial automation systems and components, SPS Nuremberg 2023 brought together more than 1,200 exhibitors of smart production solutions and attracted tens of thousands of visitors from all over the world. The event showcased the technological innovations and the latest academic achievements related to industrial manufacturing.

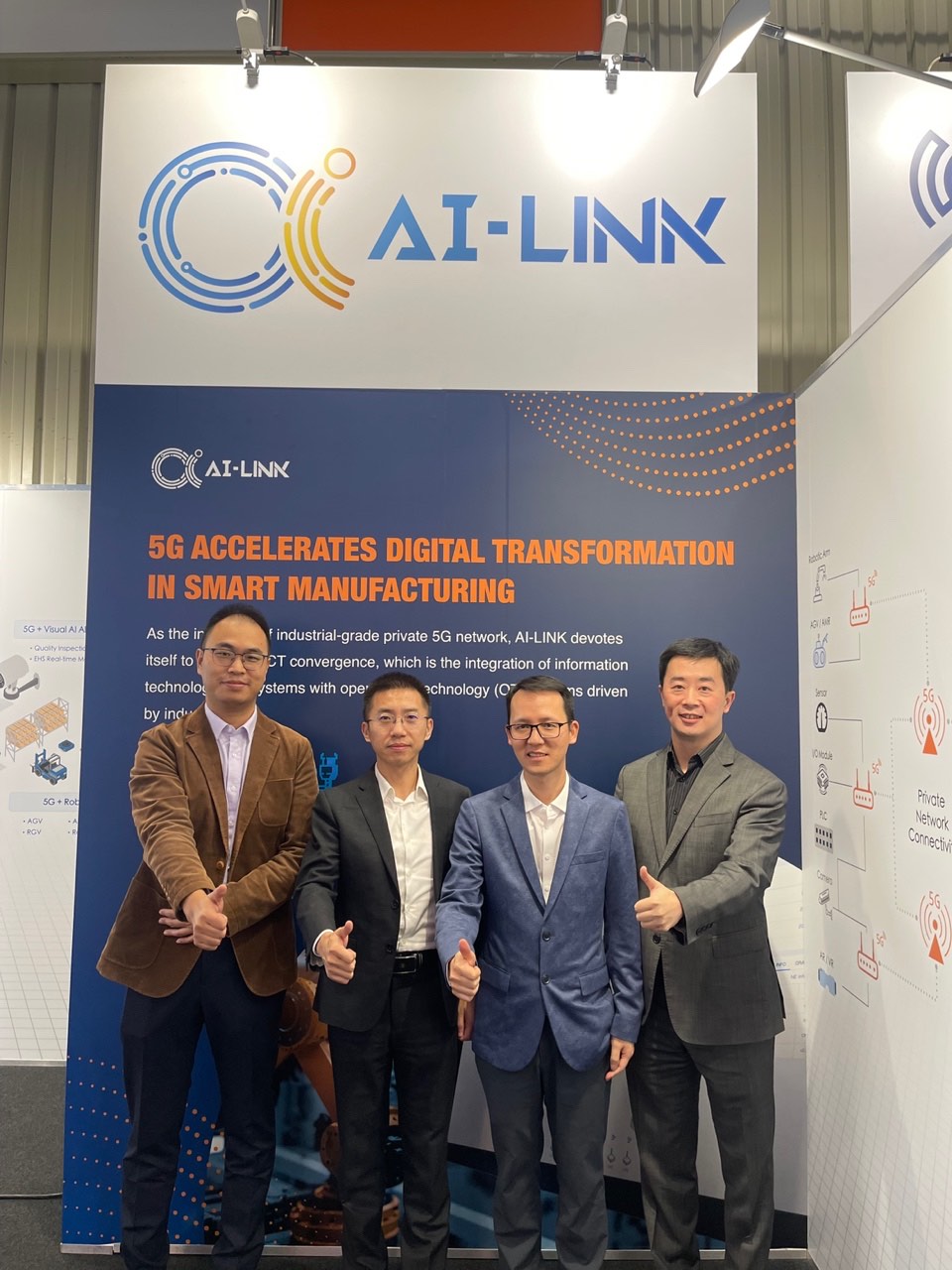

Amid China’s efforts to promote 5G + industrial Internet, industrial 5G companies from the country have accelerated their global market expansion in recent years. At SPS Nuremberg 2023, Chinese company AI-LINK was the only exhibitor specializing in end-to-end industrial 5G products and solutions. This Chinese industrial 5G supplier demonstrated its innovative capabilities to customers and experts from all over the world.

Founded in 2020, AI-LINK has visited the production lines and workshops of hundreds of companies and factories. These visits were aimed at gaining a comprehensive understanding of the status quo of digitalization as well as the needs and challenges in the process of digital transformation. The company is committed to building high-quality industrial 5G networks and providing cost-effective connectivity for industrial sites.

Opportune Time for 5G Fully-Connected Factories

China has built the world’s most extensive and advanced 5G network. In September 2022, China’s Ministry of Industry and Information Technology issued the “Guidelines for the Construction of 5G Fully-Connected Factories”, which aims to promote 5G fully-connected factories in 10,000 enterprises and create 1,000 factories of different levels and categories with distinctive characteristics and 100 benchmark factories during the 14th Five-Year Plan period. As 5G application in the industrial sector continues to increase, more and more manufacturing enterprises are accelerating their efforts to achieve the new type of industrialization.

The development of fully-connected factories is a systematic project rather than a mere combination of 5G technology and industrial Internet. With efforts focused on production lines, workshops and factories, the aim is to create advanced factories with extensive connectivity between production units, IT/OT integration, full use of data and innovative application. This, in turn, will facilitate the transition to high-end and smart manufacturing and address the challenges faced by traditional manufacturing companies, such as difficulties in improving productivity and achieving on-demand customization.

At SPS Nuremberg 2023, AI-LINK shared its successful practices in developing 5G fully-connected factories with manufacturing exhibitors and visitors from around the world. Over the past three years, AI-LINK has worked with telecom operators and industrial companies to successfully deploy industrial 5G at various sites in industries such as automobile manufacturing, auto parts manufacturing, tobacco industry, open-pit mining, and new energy industry. The 5G network has enabled deterministic connectivity between PLC masters and slaves and between IT and OT on production lines. It enables production and management teams to collect information from sensors in real time and provides a stable and reliable network for automated guided vehicles (AGVs) in unattended warehouses. Productivity has been improved across the board and factories are more flexible in adapting production line capacity to rapidly changing market demand.

Industrial 5G Revolutionizes Manufacturing

Four years after the commercialization of 5G, the 5G + industrial Internet initiative is revolutionizing manufacturing. In the unmanned workshops of 5G-connected factories, it is common to see parts and components orderly transferred along assembly lines, tall robotic arms skillfully sorting materials and AGVs shuttling between them. One goal of the 5G + industrial Internet initiative is to make production lines increasingly intelligent so that companies can increase their productivity and cost-efficiency and accelerate the transition to digital, networked and intelligent manufacturing.

For example, in a 5G fully-connected factory project by AI-LINK, the application of digital technologies such as flexible automation, predictive analytics, digital twin and 5G in procurement, production and delivery processes enabled the digital transformation and upgrading of the end-to-end value chain. Transparent and efficient automated supply chain management in the procurement process enhanced the factory’s on-time delivery rate by 30%. In the production process, the 5G-connected flexible production lines shortened time to market by 25%. In the delivery process, intelligent and flexible warehouse solutions significantly improved warehouse flexibility and efficiency, resulting in a 52% reduction in storage space.

In response to China’s call to advance the new type of industrialization, AI-LINK is accelerating the application of industrial 5G in core production processes in various industrial and manufacturing sectors. In its endeavor, AI-LINK remains committed to independent research and development. The company promotes the integration of products from different fields and develops new products using innovative technologies. AI-LINK offers a wide range of products, from lightweight 5G core networks to industrial 5G gateways tailored to industrial sites, from edge cloud computing platforms to wireless units for industrial 5G. They serve as a constant driving force for the intelligent and digital transformation of the manufacturing industry.

SPS Nuremberg 2023 has come to an end, but the efforts to innovate and collaborate in the field of industrial 5G will not stop. Every company has a stake in the 5G era. Only through joint efforts can a resilient and elastic ecosystem of supply and demand be created.